Quickly advance your Medical

Device Program

With technology advancing at such a rapid pace, choosing the right, agile manufacturing partner delivers the strategic “time-to-market” competitive advantage you want with the ability to easily adapt and quickly adjust the scalability you need.

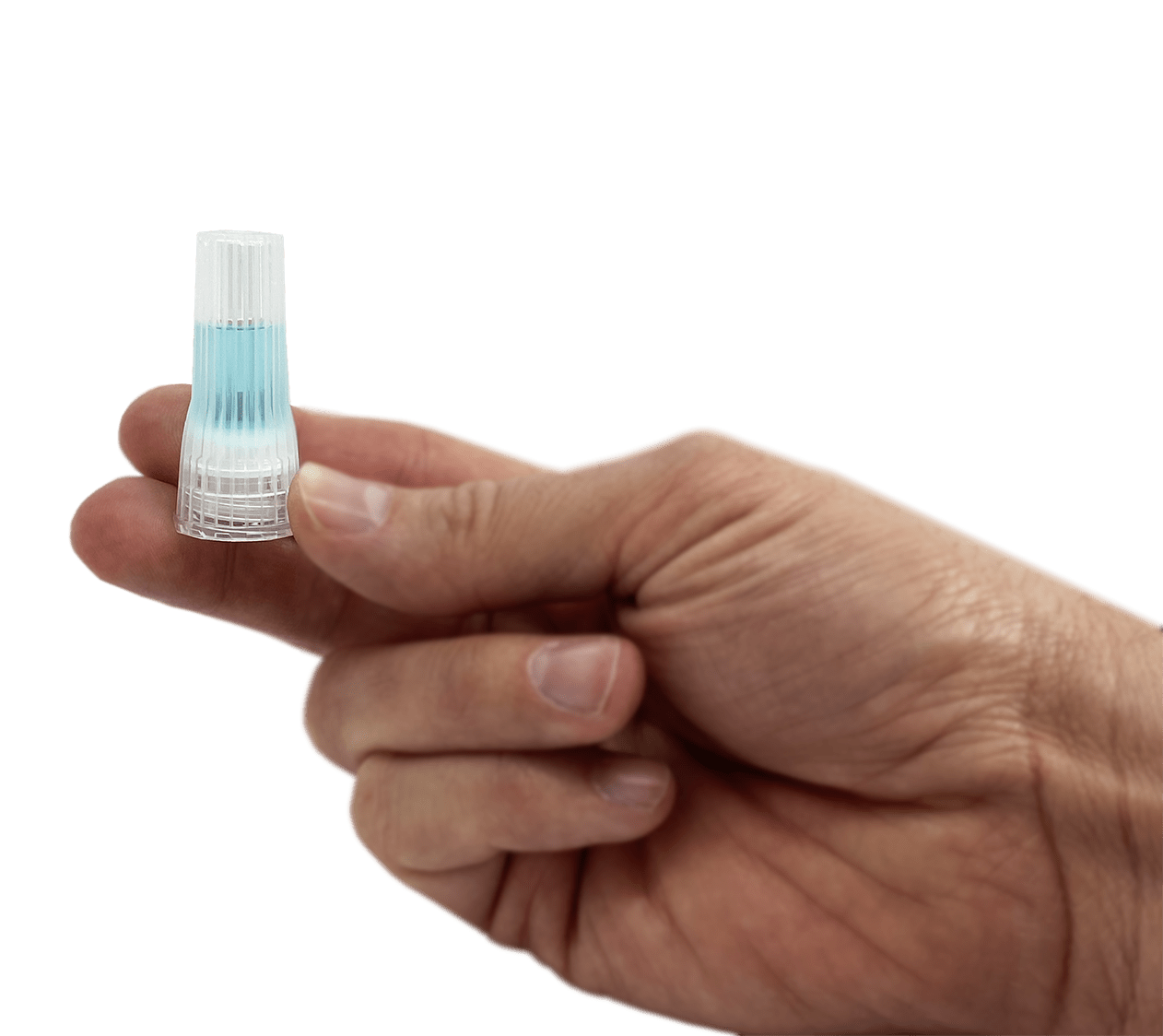

Specializing in all-electric, automated, close-tolerance, thermoplastic medical device injection molding, Spectrum provides a fully integrated total concept solution from design and tooling to production, specialized kitting, custom packaging, and direct-to-user fulfillment. Spectrum’s state-of-the-art fully electric machines, ranging from 110 to 200 tons, occupy two dedicated clean rooms fully optimized for top-quality performance. This cleaner, faster, repeatable, and energy-efficient operation uniquely provides a predictable, more precise, and fully automated process for consistently higher quality parts without error 24-hours a day 7-days a week.

- State-of-the-Art Facilities

- Rapid & On-Demand Concept Prototyping

- Quick Mold Validation & Qualification Turnarounds

- R&D Scientists and Engineers

- Fully Automated Error-Free Machine Processes

- Expert Tool Maintenance

- Scalability Program Designed to Match your Needs

- Multi-Component Molding

- Overflow Molding & Manufacturing Support According to GMP Standards

- Tight Precision & Repeatability with Lower Unit Costs, Less Waste & Lower Scrap Rates

- Shorter Start-up Times & 70% Energy Savings

- Documented preventative maintenance program with regular visual and dimensional part inspections

Quickly advance your Medical

Device Program

With technology advancing at such a rapid pace, choosing the right, agile manufacturing partner delivers the strategic “time-to-market” competitive advantage you want with the ability to easily adapt and quickly adjust the scalability you need.

Specializing in all-electric, automated, close-tolerance, thermoplastic medical device contract manufacturing injection molding, Spectrum provides a fully integrated total concept solution from design and tooling to production, specialized kitting, custom packaging, and direct-to-user fulfillment. Spectrum’s state-of-the-art fully electric machines, ranging from 110 to 200 tons, occupy two dedicated clean-rooms fully optimized for top-quality performance. This cleaner, faster, repeatable, and energy-efficient operation uniquely provides a predictable, more precise, and fully automated process for consistently higher quality parts without error 24-hours a day 7-days a week.

- State-of-the-Art Facilities

- Rapid & On-Demand Concept Prototyping

- Quick Mold Validation & Qualification Turnarounds

- R&D Scientists and Engineers

- Fully Automated Error-Free Machine Processes

- Expert Tool Maintenance

- Scalability Program Designed to Match your Needs

- Overflow Molding & Manufacturing Support According to GMP Standards

- Tight Precision & Repeatability with Lower Unit Costs, Less Waste & Lower Scrap Rates

- Shorter Start-up Times & 70% Energy Savings

- Documented preventative maintenance program with regular visual and dimensional part inspections

Concept Rapid Tooling

& 3D Printing

Automated Precision

Molding

All Experienced &

Well Trained Techs

Fully Integrated Development Solutions

Comprehensive Facilities & Integrated Capabilities

Dedicated account management ensures processes, resources, compliance, and costs are managed effectively.

Additional options include customized packaging and labeling, unique device serialization, specialized kitting, chemical formulation, and direct-to-patient global fulfillment.

Superior Engineering

& Technical Expertise

With over 50 years of combined experience, credibility, and some of the industry’s most talented designers, engineers, scientists, and expert toolmakers Spectrum delivers the needed cross-functional support that ensures quality, precision tolerances, and optimized cycle times from design inception to product release.

Superior Engineering

& Technical Expertise

With over 50 years of combined experience, credibility, and some of the industry’s most talented designers, engineers, scientists, and expert toolmakers Spectrum delivers the needed cross-functional support that ensures quality, precision tolerances, and optimized cycle times from design inception to product release.

Metrology Lab

Validations

Faster production of the most accurate parts from the highest measure of precision.

Metrology has had a critical role to play in ensuring that accurate measurements are available to assess the performance of new diagnostic tools. Increase measurement accuracy and reduce measurement uncertainty due to temperature and humidity fluctuations for any of your mold inspection, validation, or qualification needs.

Associations, Memberships

& Credentials

Associations, Memberships

& Credentials

Ready to talk real Molding Solutions Customized to fit your Product Strategy?